China Wholesale 3 Flute Solid Carbide Roughing End Mills Factory - Flat End Milling HSS Flat End Mills 6mm – 20mm – MeiWha

China Wholesale 3 Flute Solid Carbide Roughing End Mills Factory - Flat End Milling HSS Flat End Mills 6mm – 20mm – MeiWha Detail:

Center cutting end mills can be used for plunging operations (axial milling), and can also be used in side milling operations (radial milling). Non-center cutting end mills may only be used in side milling applications. The most common material used for end mills is tungsten carbide, but HSS (high speed steel) and Cobalt (high speed steel with cobalt as an alloy) are also available.

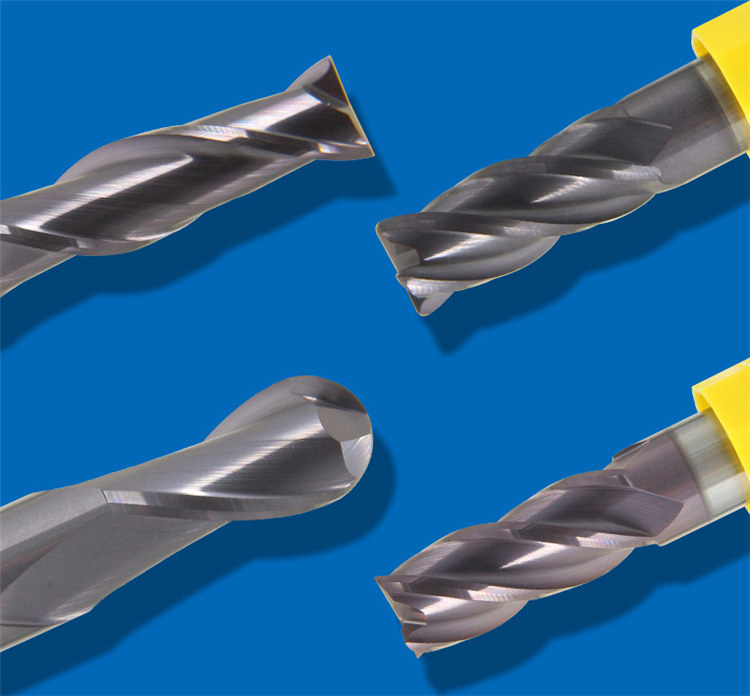

Flat end mills are used for roughing operations, cutting 2D shapes like engravings and circuit boards, and flat-sided 3D shapes. You can use these carbide end mills to cut a square edge into metal, wood, wax, and plastic.

They are available in a wide variety of diameter sizes from 1mm to 20mm.

Meihua milling cutter 55 degrees: MW7050 series, coating color: fuchsia, Balzers coating, Jinlu GU25UF

Bar stock, mold steel, stainless steel, general series of materials below 55 degrees, SKD11 corresponds to Chinese grades: Cr12MoV, 718 (41~47HRC hardness), NAK80 (HRC37~43), S316, Cr12MoV, C45, P20, ordinary mold steel, gray Cast iron, etc.

Meihua milling cutter 65 degrees: MW7060 high hardness series, coating color: bronze, Balzers coating, Japan

Porcelain FG08K bar material, excellent wear resistance, special cutting edge design, effectively solve the problem of tool cutting edge sticking, suitable for rough machining, semi-finishing and finishing, suitable for small cutting depth, large cutting width face milling, large cutting depth, Side cutter with small cutting width. Alloy steel Hardened steel less than 65HRC processing, SKD11,718,NAK80,S136,Cr12MoV,C45,P20 stainless steel series.

Delwa milling cutter 60 degrees: MW7060 high hardness series, coating color: Balzers-black gray, Sumitomo Japan.308 Bar stock, die steel, stainless steel general series, special cutting edge design, unequal helix angle, conducive to processing chips, suitable for processing: carbon steel alloy steel, stainless steel general processing, high alloy cast iron, SKD11,718, NAK80, S136, Cr12MoV, C45, P20.

Product detail pictures:

Related Product Guide:

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for China Wholesale 3 Flute Solid Carbide Roughing End Mills Factory - Flat End Milling HSS Flat End Mills 6mm – 20mm – MeiWha , The product will supply to all over the world, such as: Tunisia, British, Atlanta, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.