China Wholesale Flat Milling Factory - Ball Nose Milling HSS Round Nose Milling 6mm – 20mm – MeiWha

China Wholesale Flat Milling Factory - Ball Nose Milling HSS Round Nose Milling 6mm – 20mm – MeiWha Detail:

They can be single end or double end and they can be made from solid carbide or various compositions of high speed steel. They can be general purpose or high perfomance geometries. They can be used used for milling a large corner radius, grooving with a full radius, and contour or profile milling. The smaller diameters can be used for engraving. They are available in a wide variety of standard sizes and lengths.

Carbide ball end mills are used for cutting curves and 3D shapes into metals, woods, waxes, and plastics. The different angles produced by the ball-shaped bit allow you to create a wealth of 3D shapes. Cuts made with a ball end mill will have a slightly rounded shape.

They are available in a wide variety of diameter sizes from 1mm to 20mm.

Meihua milling cutter 55 degrees: MW7050 series, coating color: fuchsia, Balzers coating, Jinlu GU25UF

Bar stock, mold steel, stainless steel, general series of materials below 55 degrees, SKD11 corresponds to Chinese grades: Cr12MoV, 718 (41~47HRC hardness), NAK80 (HRC37~43), S316, Cr12MoV, C45, P20, ordinary mold steel, gray Cast iron, etc.

Meihua milling cutter 65 degrees: MW7060 high hardness series, coating color: bronze, Balzers coating, Japan.

Porcelain FG08K bar material, excellent wear resistance, special cutting edge design, effectively solve the problem of tool cutting edge sticking, suitable for rough machining, semi-finishing and finishing, suitable for small cutting depth, large cutting width face milling, large cutting depth, Side cutter with small cutting width. Alloy steel Hardened steel less than 65HRC processing, SKD11,718,NAK80,S136,Cr12MoV,C45,P20 stainless steel series.

Delwa milling cutter 60 degrees: MW7060 high hardness series, coating color: Balzers-black gray, Sumitomo Japan.308 Bar stock, die steel, stainless steel general series, special cutting edge design, unequal helix angle, conducive to processing chips, suitable for processing: carbon steel alloy steel, stainless steel general processing, high alloy cast iron, SKD11,718, NAK80, S136, Cr12MoV, C45, P20.

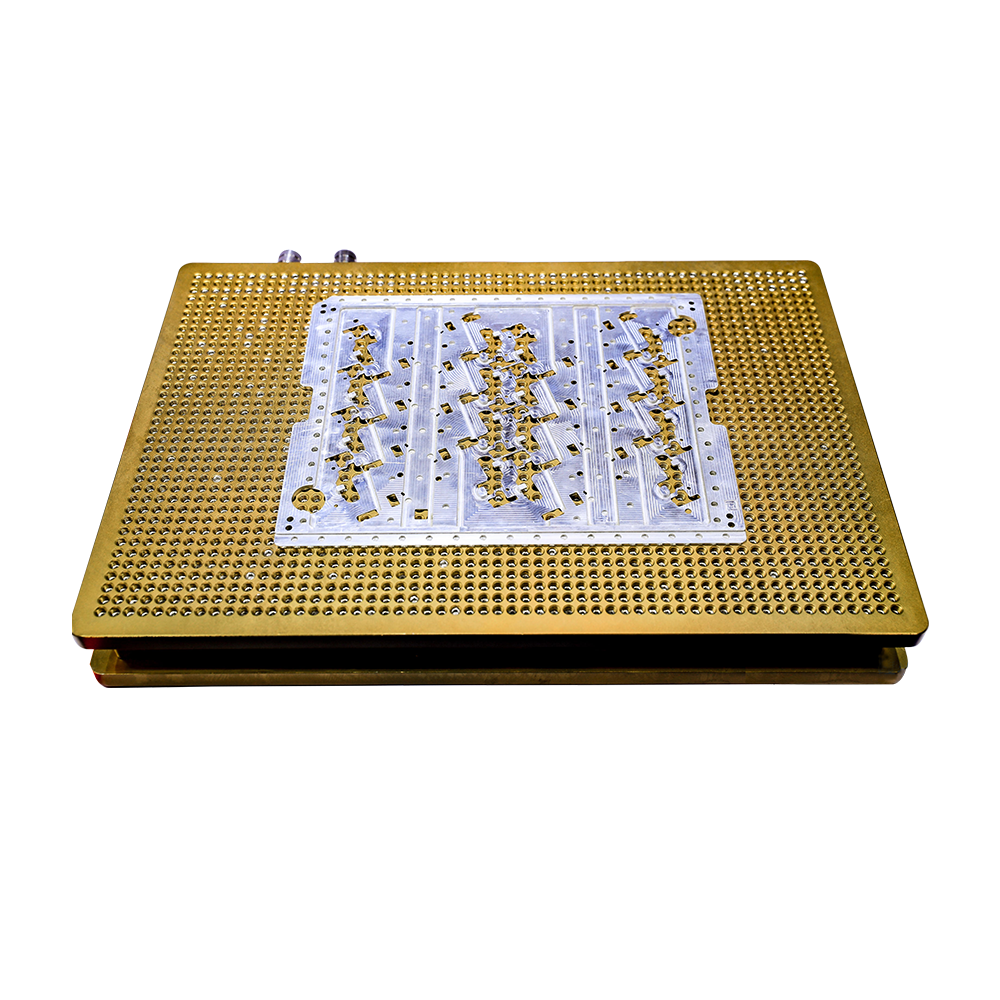

Product detail pictures:

Related Product Guide:

Our personnel are generally in the spirit of "continuous improvement and excellence", and together with the outstanding top quality merchandise, favorable price tag and fantastic after-sales solutions, we try to gain every single customer's rely on for China Wholesale Flat Milling Factory - Ball Nose Milling HSS Round Nose Milling 6mm – 20mm – MeiWha , The product will supply to all over the world, such as: Borussia Dortmund, Johor, Luxemburg, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.