China Wholesale For Stainless Steel & Titanium Alloy Suppliers - Complex Chamfer – MeiWha

China Wholesale For Stainless Steel & Titanium Alloy Suppliers - Complex Chamfer – MeiWha Detail:

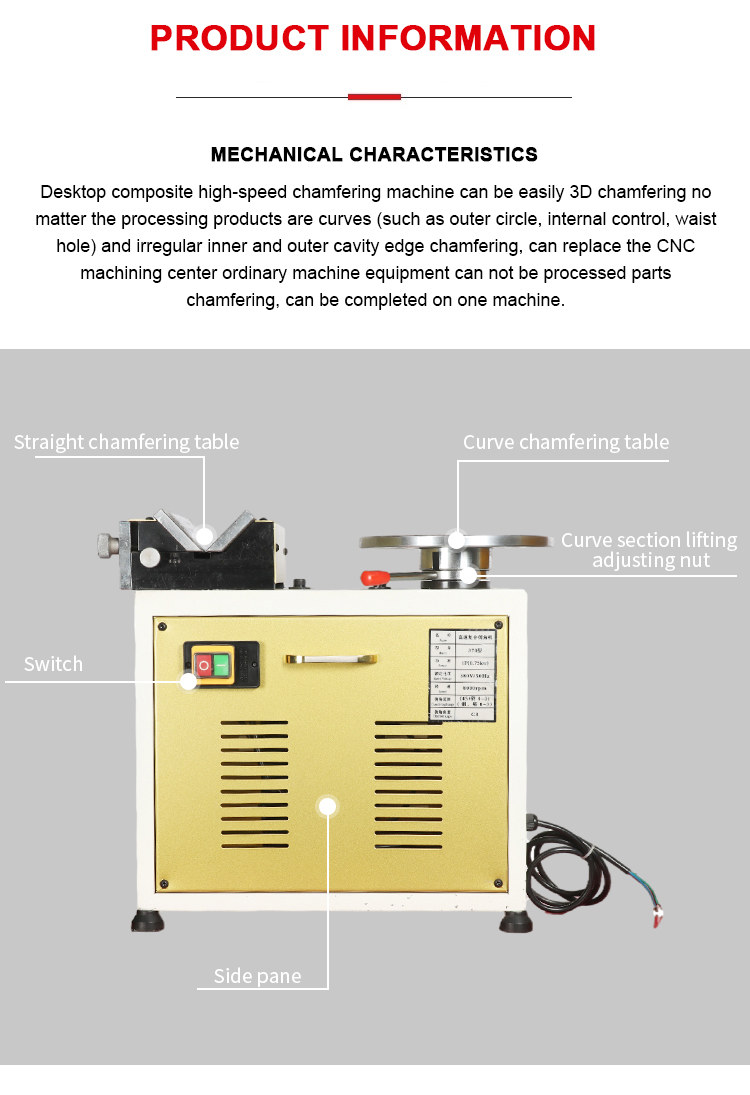

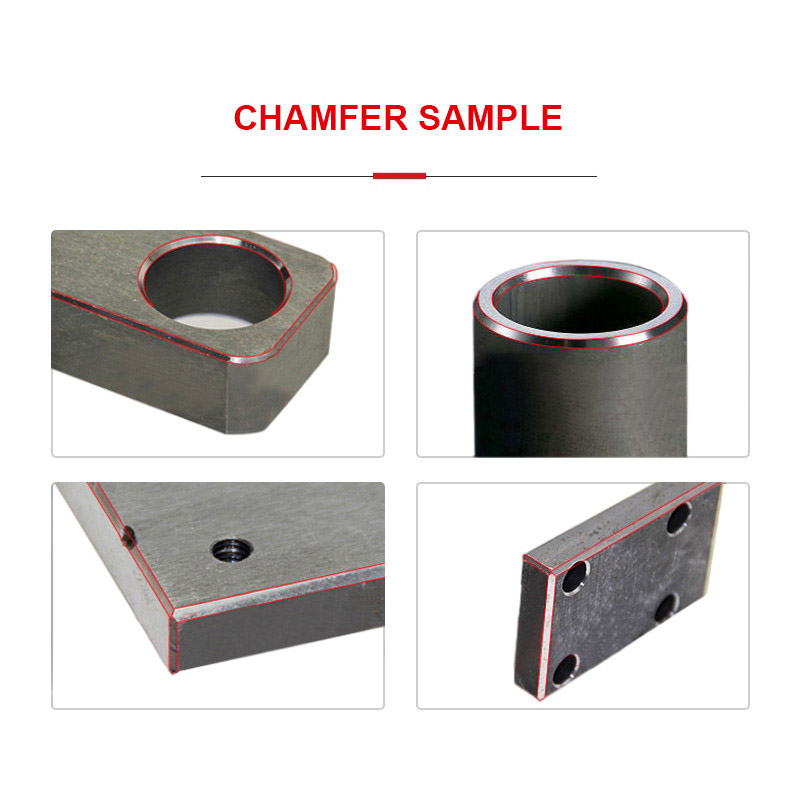

Chamfering is a difficult task in small areas. A complex chamfer is one of the most useful and high efficiency producing machine. One can use a complex chamfering machine for smoothening of edges at a precise angle. This type of chamfering machine can be opted for materials like marble, glass, and other similar materials. Also, this is user-friendly and provides grip to the user for handling the machinery.

There are major benefits that can be obtained from using the Chamfering machine is that labouring is not required when one can use the Chamfering machine instead of hard work. The cycle of the chamfering machine works rapidly so that the procedure of cutting down the edges of large material/metals like glass, wooden furniture and many more, in a shorter period of time. With the sturdy design of the equipment, the machine can be a reliable source for shaping materials for many years. The machine is preferable by various industries as it has the ability to reduce the labour work-load and can give the fine quality cutting of metals and materials.

1.It’s suitable for reqular and irreqular parts of mechanism or mould.The angle of straight line part can be adjust from 15 degree to 45 degree.

2.It’s easy ,quick to change the cutter, no need to clamp,easy operate perfect chamfering,easy adjust, and economic,suitable for irreqular parts of mechanisms and mould.

3.The angle of straight line part can be adjust from 15 degree to 45 degree.

4.It can instead the CNC maching center and general-purpose machine tools,which can not chamfer. It is convient, fast and accurate and the best choice for chamfering.

| Model | WH-CF370 | |

| Chamfering height | 0-3mm (Straight) | 0-2.5mm(Curved) |

| Chamfering angle | 15° ~45°[Straight) | 45°(Curved) |

| Power | 380V/750W | |

| Speed | 8000rpm (Straight) | 12000rpm (Curved) |

| Layout size | 600*70mm | |

| Chamfering processing size | 0-6mm can adjust 4800rpm | |

| Dimension | 53x44x69cm | |

| Weight | 75kg | |

| The machine adopt Swedish SKF bearing and imported digital cuttings. | ||

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for China Wholesale For Stainless Steel & Titanium Alloy Suppliers - Complex Chamfer – MeiWha , The product will supply to all over the world, such as: Azerbaijan, Leicester, Singapore, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,