China Wholesale HSS Drill Manufacturers - Alloy Drill – MeiWha

China Wholesale HSS Drill Manufacturers - Alloy Drill – MeiWha Detail:

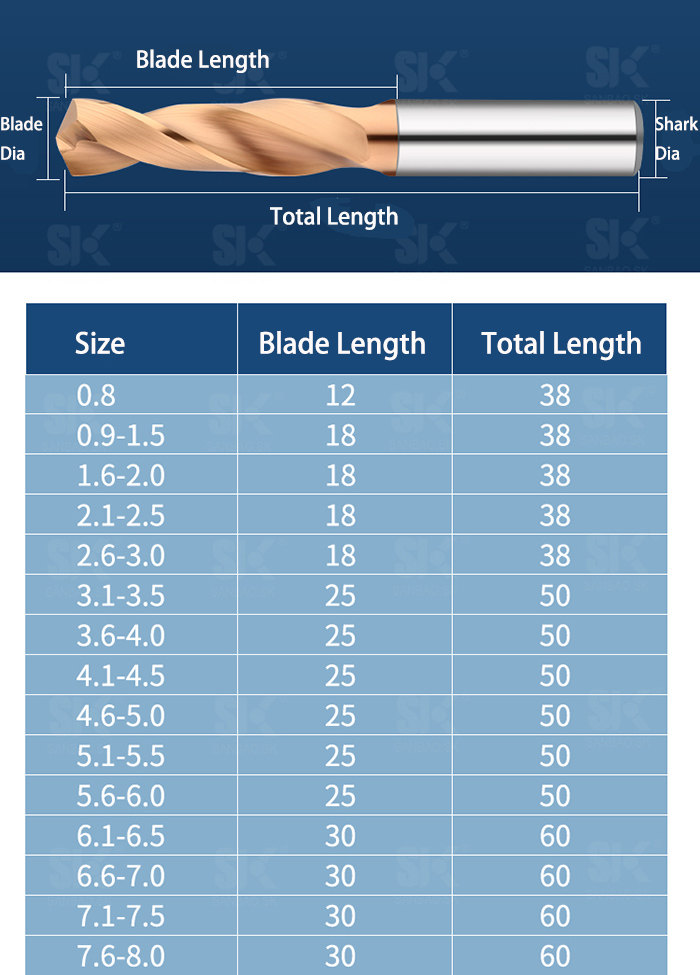

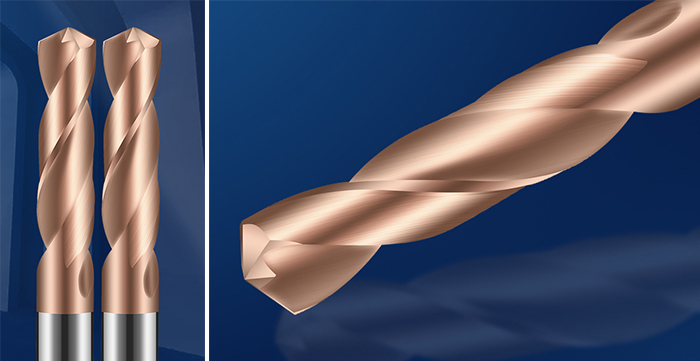

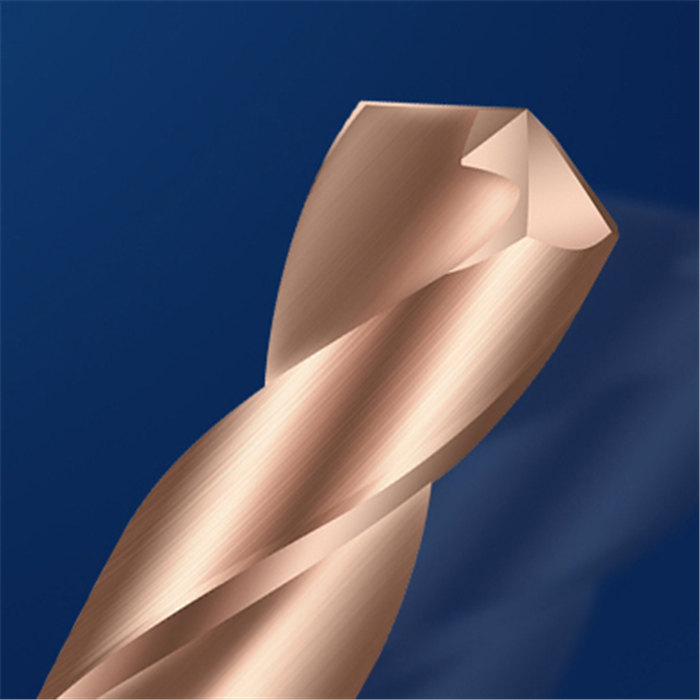

Specially-designed flutes keep these bits centered as they drill, resulting in straighter, rounder holes with tighter tolerances. Made of solid carbide for the highest accuracy and longest tool life, they are harder, stronger, and more wear resistant than high-speed steel, cobalt steel, and carbide-tipped bits. They retain a sharp, hard edge at high temperatures for the best performance on hard and abrasive material. These bits require rigid toolholding to prevent breakage and should not be used in hand-held drilling. All are jobbers’ length so they have the rigidity and length required for most applications. An titanium nitride (TIACN) coating gives them additional wear and temperature resistance.

Precautions for using cemented carbide tools

1) Cemented carbide is a hard and brittle material, which is brittle and damaged under excessive force or some specific local stress effects, and has sharp cutting edges.

2) Most of the cemented carbides are mainly tungsten and cobalt. The ingredients have a high density, so they should be handled as heavy objects during transportation and storage.

3) Cemented carbide and steel have different thermal expansion coefficients. In order to prevent stress concentration from cracking, attention should be paid to welding at an appropriate temperature.

4) Carbide cutting tools should be stored in a dry, away from corrosive atmosphere.

5) During the cutting process of cemented carbide tools, chips, chips, etc. cannot be prevented. Please prepare necessary labor protection supplies before machining.

6) If cooling fluid or dust collection equipment is used in the cutting process, in consideration of the service life of the machine tool and cutting tools, please use cutting fluid or dust collection equipment correctly.

7) Please stop using the tool with cracks during processing.

8) Carbide cutting tools will become dull and lose strength due to long-term use. Please don’t let non-professionals sharpen them. 9) Please keep the worn out alloy tools and the fragments of alloy tools properly to prevent damage to others.

Product detail pictures:

Related Product Guide:

We have many excellent staff members good at marketing, QC, and dealing with kinds of troublesome problem in the production process for China Wholesale HSS Drill Manufacturers - Alloy Drill – MeiWha , The product will supply to all over the world, such as: Brazil, Sri Lanka, Madras, Based on products and solutions with high quality, competitive price, and our full range service, we have accumulated experienced strength and experience, and we've built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality items and passionate service. Let's open a new chapter of mutual benefit and double win.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!