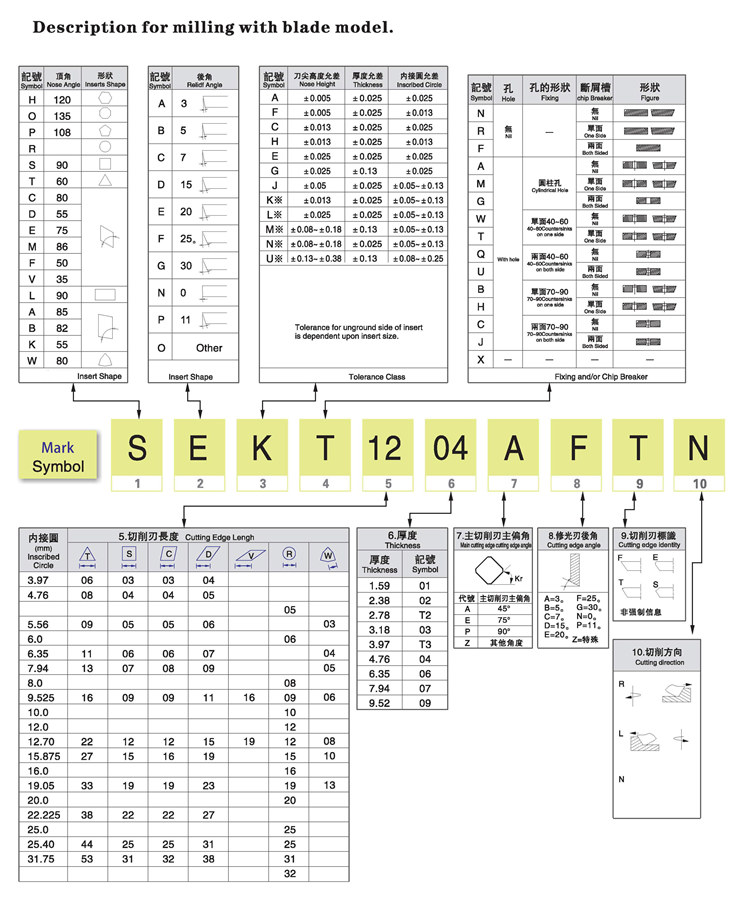

China Wholesale Round Milling Inserts Factory - For Steel & Iron Casting – MeiWha

China Wholesale Round Milling Inserts Factory - For Steel & Iron Casting – MeiWha Detail:

Video

As a full-line supplier of metalworking tools, MeiWha provides a full ISO range of quality tools. All standard geometries are supplied, including the most popular trigon shape.

These semi-triangular turning inserts are used for axial and face turning and feature three 80° corner cutting edges on each side of the insert.

They replace the rhombic inserts that had only two cutting edges, thus saving production time and cost while maximizing insert life.

MeiWha offers a variety of unique chipformers and grade combinations that provide solutions to most of modern industry’s machining needs.

MeiWha’s ISO turning line provides a complete solution for all types of applications and materials, with innovative insert geometries combined with the world’s leading carbide grades designed to meet high customer demands for tool life and productivity.

MeiWha doubles the cutting edges on positive rake inserts intended for general turning applications. This economical solution for 80 degree turning provides double-sided robust and positive 4 cutting-edged inserts that easily replace the positive 2 cutting edged inserts. Their special design, assuring better insert positioning and stability to guarantee longer insert tool life.

Introduction of various materials.

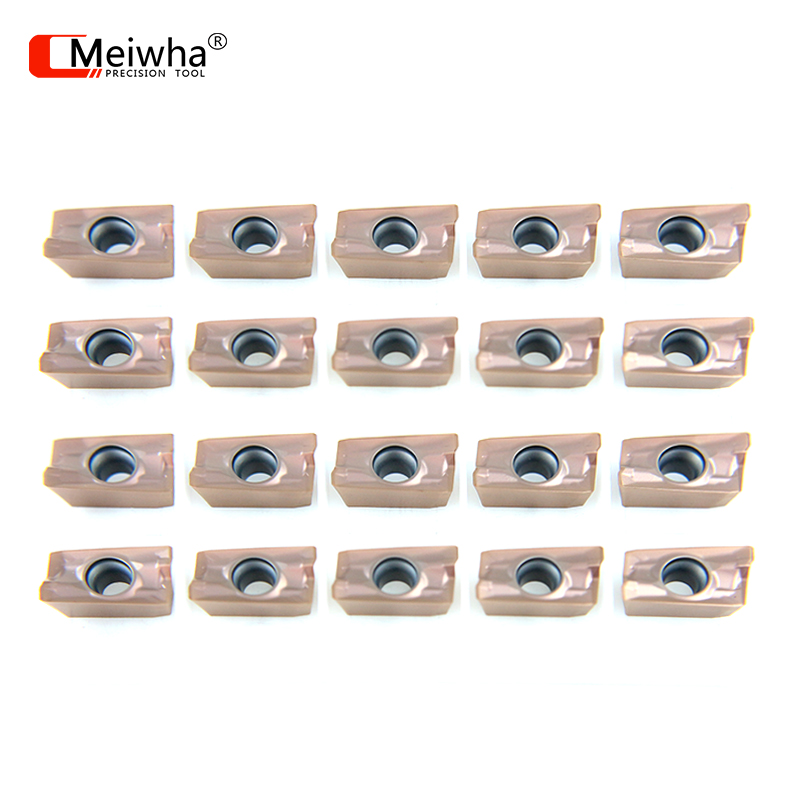

MR8030: Coating color: bronze with Balzers HE coating.

Performance: steel parts, stainless steel, relative to the above coating, The materials below 55 degrees.

MW7050: Coating color: black, a high-end coating process developed by Balzers HE and AD.

Performance: hardened steel, modulated steel and other high hardness, difficult to process materials below 65 degrees.

MW2525: Cermet, silicon oxide,

Performance: high hardness, good wear resistance, although the hardness is not as good as PCD and CBN, but much higher than carbide and high-speed steel tools. It has a long service life, reduces the number of tool changes, and greatly improves production efficiency. High temperature resistance, good heat resistance, good chemical stability, not easy to stick to the knife, and corrosion resistance. Mainly used for high-speed machining and semi-finish machining, for high-speed cutting of ordinary steel and cast iron that cannot be machined by carbide inserts, and for processing difficult-to-machine materials.

Product detail pictures:

Related Product Guide:

We regularly perform our spirit of ''Innovation bringing progress, Highly-quality making certain subsistence, Administration marketing benefit, Credit score attracting customers for China Wholesale Round Milling Inserts Factory - For Steel & Iron Casting – MeiWha , The product will supply to all over the world, such as: Orlando, Egypt, Gabon, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.