China Wholesale Round Roughing Milling Inserts Factories - PCD – MeiWha

China Wholesale Round Roughing Milling Inserts Factories - PCD – MeiWha Detail:

As a full-line supplier of metalworking tools, MeiWha provides a full ISO range of quality tools. All standard geometries are supplied, including the most popular trigon shape.

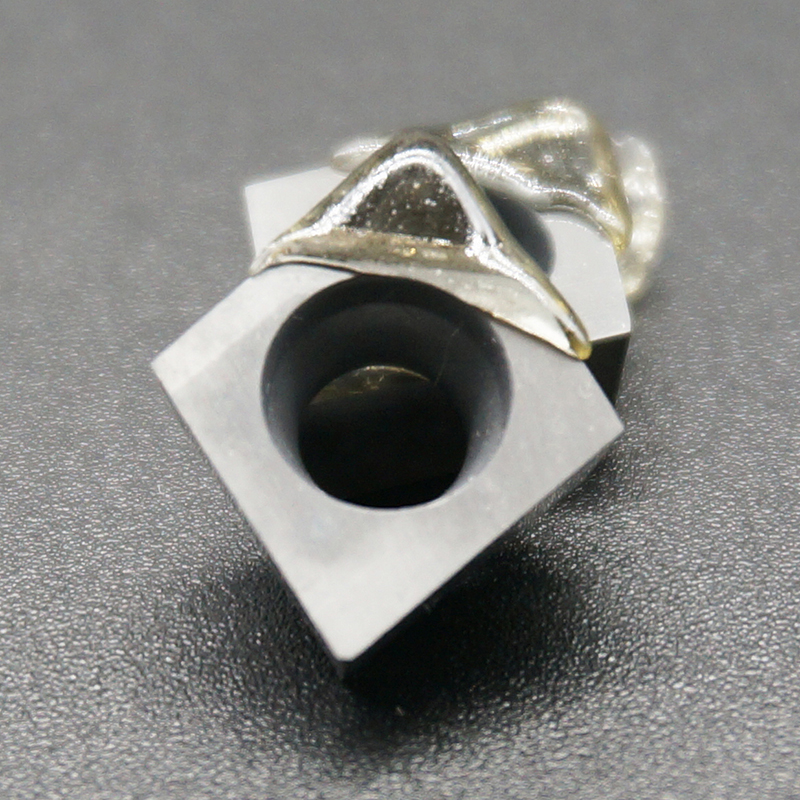

These semi-triangular turning inserts are used for axial and face turning and feature three 80° corner cutting edges on each side of the insert.

They replace the rhombic inserts that had only two cutting edges, thus saving production time and cost while maximizing insert life.

MeiWha offers a variety of unique chipformers and grade combinations that provide solutions to most of modern industry’s machining needs.

MeiWha’s ISO turning line provides a complete solution for all types of applications and materials, with innovative insert geometries combined with the world’s leading carbide grades designed to meet high customer demands for tool life and productivity.

MeiWha doubles the cutting edges on positive rake inserts intended for general turning applications. This economical solution for 80 degree turning provides double-sided robust and positive 4 cutting-edged inserts that easily replace the positive 2 cutting edged inserts. Their special design, assuring better insert positioning and stability to guarantee longer insert tool life.

PCD: abbreviated as diamond, performance: has the characteristics of high hardness, high compressive strength, thermal conductivity and wear resistance, etc. Available at high machining accuracy and machining efficiency are obtained in high-speed cutting.It is suitable for processing non-ferrous materials, such as high silicon aluminum, metal matrix composite materials and carbon fiber reinforced plastics. PCD using a large amount of cutting fluid can also be used for super finishing of titanium materials. Mirror processing can be achieved on ultra-precision lathes.

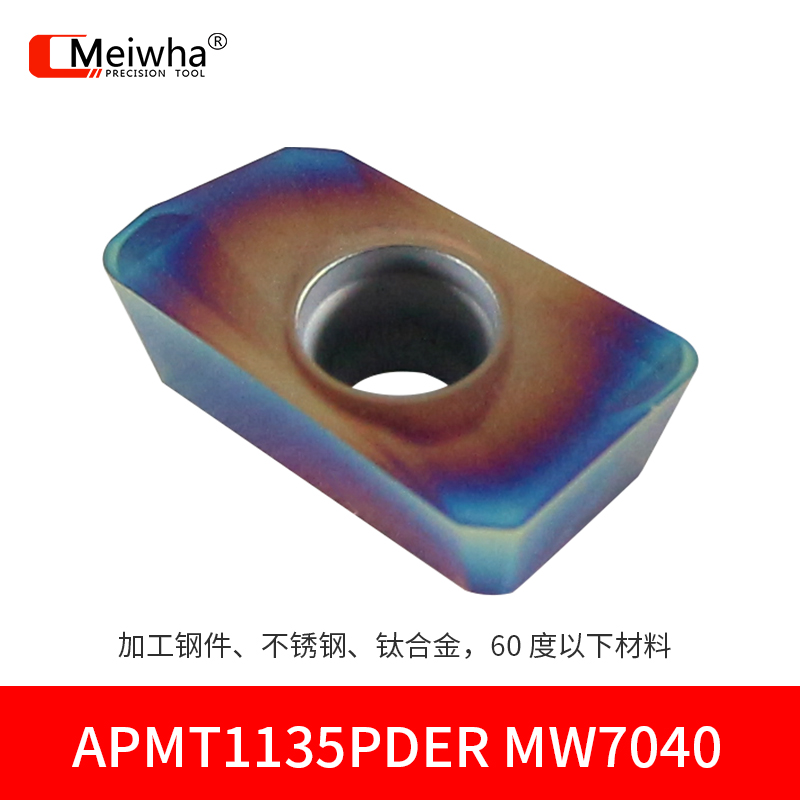

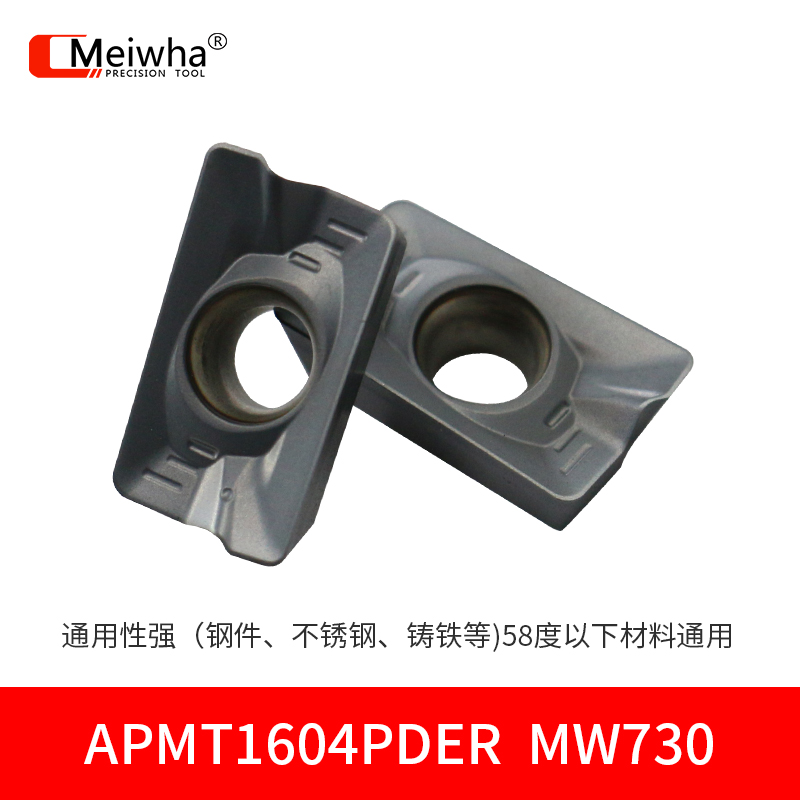

Product detail pictures:

Related Product Guide:

In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for China Wholesale Round Roughing Milling Inserts Factories - PCD – MeiWha , The product will supply to all over the world, such as: Durban, Las Vegas, Orlando, Custom orders are acceptable with different quality grade and customer's especial design. We are looking forward to establish the good and successful cooperation in business with long terms from the customers of all over the world.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!