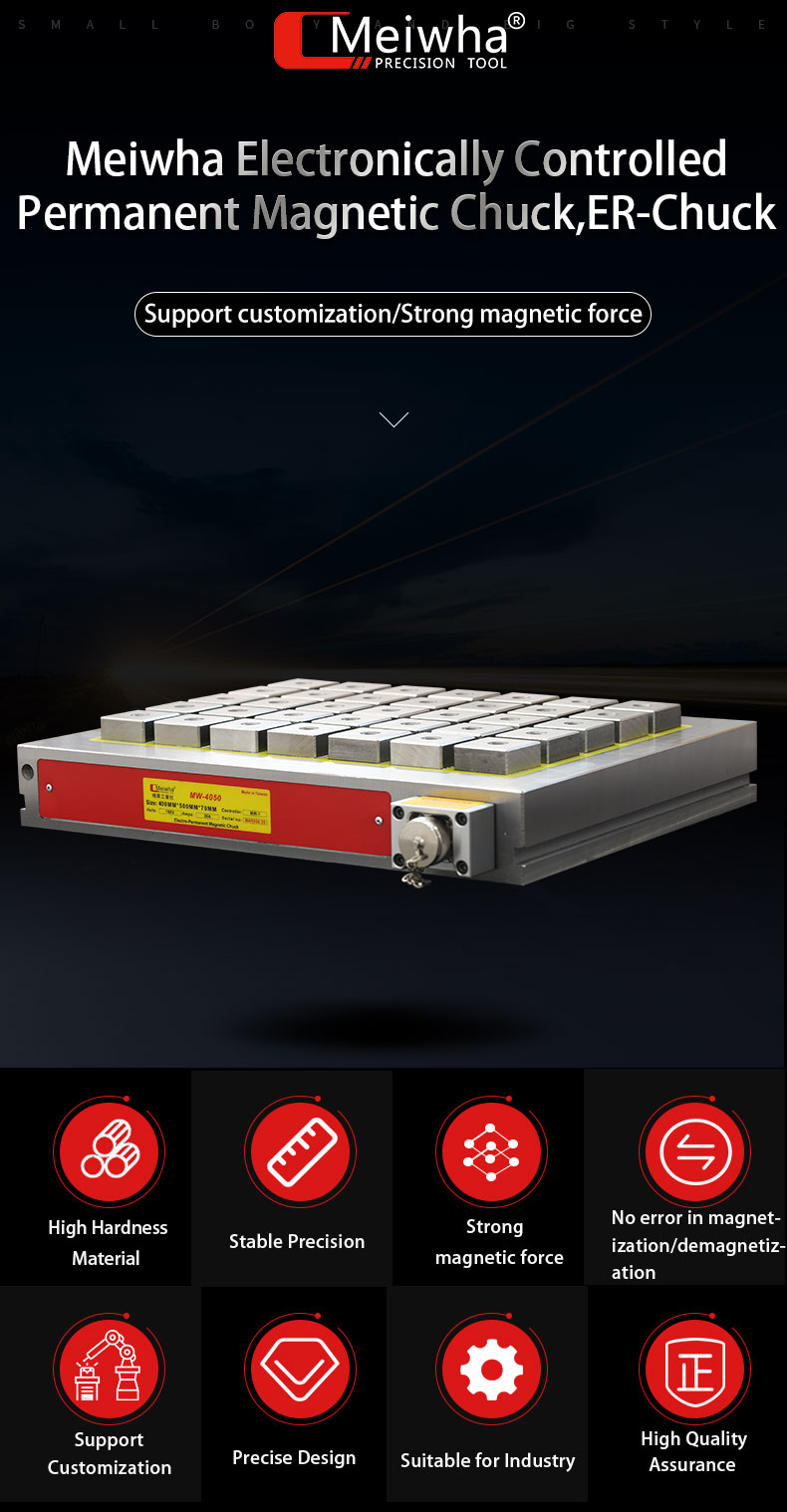

Electro Permanent Magnetic Chucks For CNC Milling

Electro permanent magnetic milling chuck is the best magnetic clamping tool at present, which use electro pulse to "open and close". It is very safe and reliable when workpiece is attracted by magnetic chuck in process. After attract workpiece by magnetism, the magnetic chuck holds the magnetism permanently. "Open and close" time is less than 1 second, electric pulse consume few energy, the magnetic chuck won’t be thermal deformation. it is widely used to clamp workpiece when it is machined by milling machine and CNC.

Features and Advantages

1 Once clamping is available to process five sides, workpieces are allowed to be larger than the working platform.

2 Save 50%-90% piece handing time, improve the working efficiency of labor and machine tool, lower labor work intensity.

3 Not required to change machine tool or production line, as the workpiece is stressed evenly, workpiece won’t transform, no shaking in process. Extend working life of cutting tools.

4 The magnetic chuck is applicable to clamp various components under heavy or high-speed milling in horizontal and vertical type, is also applicable to curving, irregular, difficult clamping, batch and particular workpieces. It is applicable to rough and finish machining.

5 Constant clamping force, not require electricity when it is in clamp status, no radiation of magnetic line, no heating phenomenon.

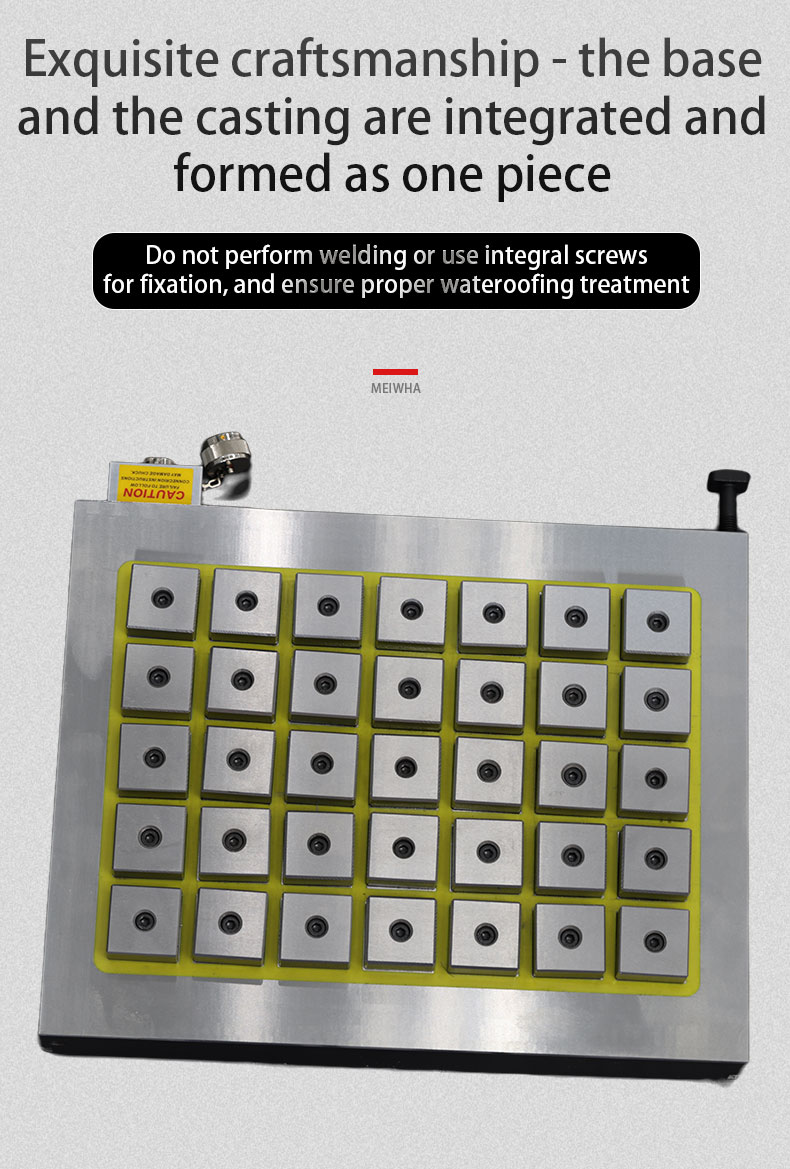

High Accuracy: Construction from mono-block steel case

No Heat Generation: Requires control to turn “On” or “Off”, then unplug for use

Maximize Part Access: Top tooling allows for workpiece smaller than magnetic face to be machined on 5 sides

Fully Vacuum Potted: Vacuum filled with dielectric resin which becomes a solid block with no voids or moving parts

Highest Power: Dual magnet system produces a pull force potential per pole pair of 1650 lbf for maximum grip

Palletizing: Mounts on any referencing systems. Power only required to turn magnet “On” or “Off”

Flexible: One work holding solution for multiple part geometries

Safety: Not affected by power failure and fully sealed and potted against liquids