The tool holder heat shrink machine is a heating device for heat shrink tool holder loading and unloading tools. Using the principle of metal expansion and contraction, the heat shrink machine heats the tool holder to enlarge the hole for clamping the tool, and then puts the tool in. After the temperature of the tool holder cools down, clamp the tool. The required accuracy of the tool must be more than 6h.

The precision of this heat shrink tool holder is very high. Generally, this tool holder can only be heated up to 3,000 times, so the tool is generally not removed after it is clamped, and it is used directly the next time. Mold factories with high precision requirements will use large quantities of heat shrink tool holder and heat shrink machines.

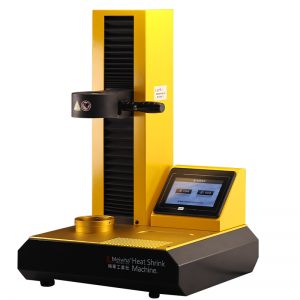

The tool holder heat shrink machine is used in conjunction with the heat shrink tool holder to ensure that the tool holder has a strong and stable clamping force. The heat shrink machine’s heating process is electronically controlled to ensure tool change accuracy, and the return disk protection prevents the tool and tool holder from being burned. The special magnetic field effectively reduces the tool change time. Heating and cooling are at the same position to reduce the risk of scalding when moving the tool. Local heating protects the handle. The special magnetic field has higher heating efficiency, and the heating point can be moved to the appropriate position to improve tool change efficiency.

Meiwha automatic intelligent heat shrink machines are widely used in all industries around the world, including the aerospace industry, mold manufacturing, micro processing and machining fields.

Post time: Dec-10-2024