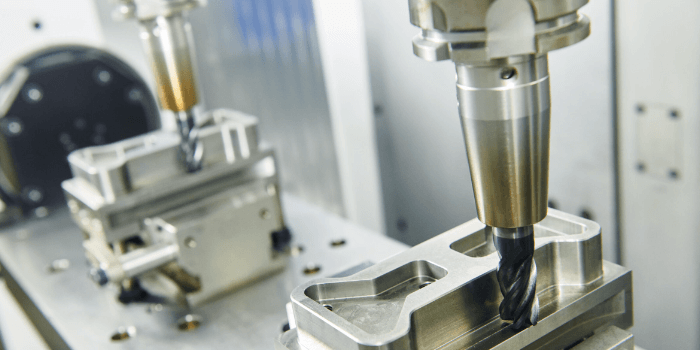

Shrink fit tool holder have been widely used in CNC machining centers due to their high precision, high clamping force and convenient operation. This article will explore the shrinkage of shrink fit tool holder in depth, analyze the factors affecting the shrinkage, and provide corresponding adjustment methods to help everyone better understand and use shrink fit tool holders.

1. What is the shrinkage of shrink fit tool holders?

A. The shrinkage of shrink fit tool holders refers to the value of the reduction of the inner hole diameter after the shank is heated. This value is usually measured in microns (μm) and directly affects the clamping accuracy and stability of the tool.

B. The size of the shrinkage is closely related to factors such as the material, size and heating temperature of the shank. Generally speaking, the larger the size of the shank, the greater the shrinkage.

C. Understanding the shrinkage of shrink fit tool holders is crucial to choosing a suitable shank and ensuring machining accuracy.

2. What are the factors that affect the shrinkage of shrink fit tool holders?

A. Material: shrink fit tool holders of different materials have different thermal expansion coefficients, resulting in different shrinkage. For example, a shank made of high-quality spring steel usually has a more stable shrinkage.

B. Heating temperature: The higher the heating temperature, the greater the expansion of the handle, and the greater the shrinkage after cooling. However, too high a temperature may damage the handle, so the heating temperature needs to be strictly controlled.

C. Cooling method: The cooling method will also affect the shrinkage. For example, rapid cooling will cause a slight increase in shrinkage.

D. Handle size: The shrinkage of handles of different specifications is also different. Generally, the larger the handle size, the greater the shrinkage. We need to choose a handle of the appropriate size according to actual processing needs.

3. How to adjust the shrinkage of the heat shrink handle?

A. Choose the appropriate heating temperature: Choose the appropriate heating temperature according to the material and size of the handle. Generally, the heating temperature is between 200℃ - 300℃.

B. Control the cooling speed: Try to avoid rapid cooling and let the handle cool naturally to obtain a more uniform shrinkage.

C. Use professional heat shrink equipment: Professional heat shrink equipment can accurately control the heating temperature and time to ensure that the shrinkage of the heat shrink handle reaches the optimal state.

4. Common problems and solutions for heat shrink tool holders

A. Insufficient clamping force of tool holder: It may be because the heating temperature is not enough or the cooling speed is too fast. You can try to increase the heating temperature or slow down the cooling speed.

B. Tool holder is stuck to the tool: It may be because there are impurities in the tool holder or the surface of the tool is not clean. You need to clean the tool holder and the tool.

C. Tool holder deformation: It may be because the heating temperature is too high or the cooling speed is too fast. You need to control the heating temperature and cooling speed, and choose the appropriate heat shrink equipment.

5. Precautions for using heat shrink tool holders

A. Before heating, be sure to clean the inner hole of the tool holder and the tool handle to ensure that there are no impurities.

B. During the heating process, avoid local overheating of the tool holder.

C. During the cooling process, avoid impact or vibration of the tool holder.

D. After use, clean the tool holder in time and store it in a dry and ventilated place.

The following are questions and answers you may also be concerned about:

Q: How are the accuracy levels of heat shrink tool holders divided?

A: The precision level of shrink fit tool holders is usually divided into AT3, AT4, AT5, etc. The higher the precision, the more accurate the shrinkage control.

Q: How many times can the shrink fit tool holder be used?

A: The service life of the shrink fit tool holder is related to factors such as frequency of use and maintenance. Generally, it can be reused hundreds or even thousands of times.

Q: How to choose a suitable shrink fit tool holder?

A: When choosing a shrink fit tool holder, you need to consider factors such as the diameter of the tool, precision requirements, and processing materials, and choose the appropriate shank specifications and precision level.

The shrinkage of the shrink fit tool holder is a key factor affecting the processing accuracy. Only by choosing a suitable shank, controlling the heating temperature and cooling speed, and doing daily maintenance can the advantages of the shrink fit tool holder be fully utilized and the processing efficiency and quality be improved.

Post time: Jan-09-2025