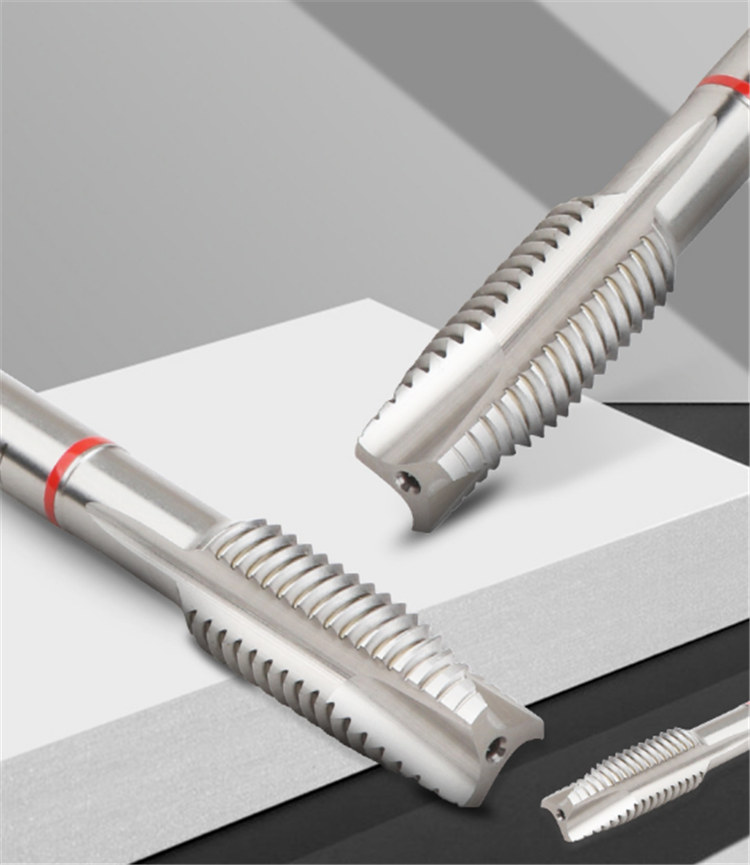

Straight Flute Tap

Straight Flute Taps are used to cut threads in blind or through holes in most materials. They are manufactured to ISO529 standard and are suitable for hand or machine cutting.

This versatile set contains three taps:

- Taper Cut (First tap) - Used for through holes or as a starter tap.

- Second Tap (Plug) - To follow the taper when tapping blind holes.

- Bottom Tap (Bottom) - For threading to the bottom of a blind hole.

All taps should be used with the corresponding drill size to ensure both cutting ease and thread efficiency.

Suitable for use on mild steel, copper, brass and aluminium.

Always wear appropriate eye protection whilst in use.

An appropriate cutting fluid should be used to maintain a cool cut.

To avoid jamming please ensure taps are relieved of pressure and reversed periodically.

Straight flute taps: the most versatile, the cutting cone part can have 2, 4, 6 teeth, short taps are used for non-through holes, long taps are used through hole. As long as the bottom hole is deep enough, the cutting cone should be as long as possible, so that more teeth will share the cutting load and the service life will be longer.